Residential Foundation Settlement Repair Solutions

Depending on the root of the foundation issue and the type of warning signs we see with the foundation, there are several methods of foundation settlement repair that are specifically designed for certain problems. Here are several common settlement repair methods:

Push Piers

Push Piers

Push piers also commonly referred to as resistance piers or hydraulically driven piers were developed from a growing need to address building settlement problems. Push pier systems utilize high-strength round steel tubing and a load transfer bracket to stabilize and/or lift settling foundations. The foundation bracket is secured against the existing footing or supporting member and pier sections are driven hydraulically into the soil below using the combined structure weight. Pier sections are continuously driven until a suitable load bearing is encountered from the resistance of the soil.

Helical Piers

Helical piers are helical screw type anchors actually look similar to that of a very large screw and are ideal for foundation settlement repair applications such as support for footers, porches, steps, stairs, chimneys, and more. They are used in many residential foundation repair and miscellaneous commercial and industrial foundation repair applications from adding support for a leaning house to supporting a large building to enable excavation and perform work below. They are one of the most widely used foundation repair applications available.

Pull-Down Micropiles

Micropiles are very similar to helical piers except they also utilize a concrete grout mixture for additional support depending on the soil. Micropiles are ideal for foundation settlement repair applications such as support for footers, porches, steps, stairs, chimneys, and more. They are used in many residential foundation repair and miscellaneous commercial and industrial foundation repair applications from adding support for a leaning house to supporting a large building to enable excavation and perform work below. They are one of the most widely used foundation settlement repair applications available.

There are many reasons for which helical piers, push piers, and micropiles have been considered the optimal solution for a foundation settlement repair project such as:

- Optional lifting of the foundation

- Ease of installation

- Minor or no vibration caused during installation

- Load of structure can immediately be transferred after installation

- Load testing is easily verified

- They install well below active soils

- Soil boring logs are not necessary

- Piers are individually load-tested during installation

- Installation torque correlates to the pier capacity

- Can be installed to support footers and slabs

Push piers have been utilized for over 100 years for such applications such as:

- Foundations

- Foundation slabs

- Equipment support

- Bridges

- Power line structures

- Elevated walkways

- Retaining walls

DESKA has licensed professional engineers on staff to properly design and supervise all push pier installations.

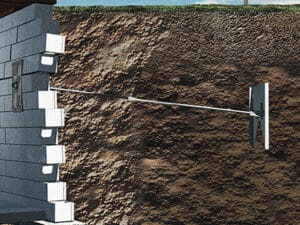

Foundation Wall Anchorage

Foundation Wall Anchorage

Using a system of plates that are connected with a long rod, we will use the outside soil to pull your bowing or buckling walls back into place and keep them there permanently. These plates are very durable and are able to be installed quickly and provide you with a stable, anchored foundation wall that will no longer be able to bow into the basement area.

Foundation Wall Stabilization

We use two potential systems to stabilize problematic foundation and basement walls. The first is an anchor system that is explained above. The second is a waler wall support system. This is designed to work in conjunction with our wall anchor plates outside the house and can work with both concrete walls as well as wooden basement walls. By anchoring a large system of supports anchored at the joist above the all, into the floor, and in the soil outside the foundation, this will provide a permanent foundation wall stabilization solution.

Mudjacking

Mudjacking is the process of injecting a pressurized cement slurry into holes drilled in a sinking concrete slab and lifting it. When the slurry has cured and hardened, the concrete slab will be leveled and good as new.

Polyurethane Jacking

Polyurethane jacking or polyjacking is very similar to mudjacking but the more modern and recent approach. Small holes are drilled into a sinking or settling slab and an expanding polyurethane foam is injected below the slab. As this foam expands to fill the void below the slab, it is lifted back into place. This method works faster, more reliable, and requires smaller holes drilled in the slab than mudjacking.

Carbon Fiber Straps

Carbon Fiber Straps

Carbon fiber and Kevlar grid straps are designed for stabilizing both poured concrete and block walls. Due to the extreme high strength to weight ratio, carbon fiber reinforcement is the settlement repair material of choice for bowed basement walls, bridge columns, and concrete beams to restore and maintain structural integrity.

Carbon fiber is a proven alternative to steel for externally reinforcing structural substrates in residential and commercial applications. Carbon fiber is highly effective at externally adding tensile strength to concrete. It is superior to steel since it is stronger, lighter weight, and non-corrosive. It also can be bonded to the surface of a concrete structure at any time to prevent bowing and cracking after a structure has been built. This allows limitless applications for new construction, repairs, and retrofits.

Kevlar Neckties

When additional shear loads are observed Kevlar neckties provide a secure anchorage system to further stabilize a foundation that has moved inwards as a result of top wall movement. Kevlar neckties may be used in conjunction with carbon fiber straps or carbon fiber staples to further enhance the structural reinforcement of a foundation wall.

Carbon Fiber Staples

Carbon fiber staples and stitching are utilized in concrete crack applications where additional tension reinforcement is needed across a crack and it is determined by an engineer that the tension load needs to be transferred a greater distance from the crack than an injected epoxy would transfer the load. Carbon fiber staples and stitching are often used in tension and shear loading applications in conjunction with epoxy injection.

Polyurethane Crack Injection

Polyurethane injection is generally used for foundation cracks and voids behind foundation walls or slabs for the purpose of preventing water intrusion. The main benefit of polyurethane foam is its ability to be highly expandable within cracks or voids behind walls for waterproofing purposes. Polyurethane injection is generally not a structural repair like epoxy injection except for with specialized structural polyurethanes in specialized applications. There are two common types of polyurethanes used in concrete crack repairs and restoration:

Hydrophobic polyurethanes – Hydrophobic polyurethane systems absorb and mix with water as is needed to complete its foaming and curing of the two components. Hydrophobic systems can expand up to 30 times of its initial volume inside cracks and voids behind walls. Advanced hydrophobic formulations are flexible and stable, and are suitable for concrete crack repairs. Hydrophobic polyurethanes bond well to concrete, do not shrink in the absence of water, and can expand enough to economically fill voids.

Hydrophilic polyurethanes – Hydrophilic polyurethane systems are very flexible,highly adhesive, and act like a sponge and will absorb as much water as is available in its surroundings during the foaming process, typically expanding two to four times its original volume. It reacts with the amount of water needed for reaction and subsequently contains the excess water within its structure, as would a sponge. In dry circumstances, some, of the excess entrapped moisture can evaporate and result in a shrinking of the foam. When moisture is again present, the foam can absorb the water and return to its original size sealing the crack. Hydrophilic polyurethanes are good where there is known or expected movement or water is always present.

Epoxy Crack Injection

Epoxy injection is a structural repair method for cracks, delamination, and/or spalls in concrete foundation walls, footers, and slabs. This method of repair involves sealing the exterior of a crack with a surface seal with attached ports and then injecting the specific viscosity and strength epoxy for the project at hand. The procedure structurally bonds concrete back together, stopping water intrusion, and stabilizes cracks and delamination. Epoxy injection is utilized for repairing dams, bridges, nuclear plants, aqueducts, tunnels, buildings, and foundations worldwide. Epoxy injection differs from that of polyurethane injection in that the purpose of epoxy injection focuses on a structural repair as opposed to solely resolving water intrusion issues.

Epoxy injection is designed for use by specialty contractors for structural concrete restoration. Epoxy injection provides a permanent solution and typically restores the affected concrete area to stronger than its original design strength.

Contact Us For Foundation Settlement Repair

If you’ve got any type of sinking or settling foundation problem, please contact us today to set up an appointment with one of our experts to evaluate your home and determine the best repair solution for you.

Push Piers

Push Piers Foundation Wall Anchorage

Foundation Wall Anchorage Carbon Fiber Straps

Carbon Fiber Straps